The Premier Aluminum Llc Statements

Table of ContentsLittle Known Questions About Premier Aluminum Llc.The 30-Second Trick For Premier Aluminum LlcThe Best Guide To Premier Aluminum LlcTop Guidelines Of Premier Aluminum Llc

(https://medium.com/@garymartin53403/about)Utilizing reduced cost and unqualified distributors can create high quality issues, and squandered time and cash in the lengthy run. To help you through the process, right here are some points to think about when picking the right steel spreading distributor.

A company that just utilizes the financial investment spreading process will certainly try to market you on why that process is best for your application (Aluminum Casting company). However what happens if utilizing the sand spreading process is best for you and your requirements? Rather, search for a supplier that provides a series of casting procedures so the best choice for YOU is picked

If dealing with a single source for all of your spreading requires is essential to you, the provider requires to be diverse in its capacities. When combined with other integrated capacities, this can aid streamline and press the supply base. When selecting the ideal spreading supplier, cautious consideration needs to be provided to quality, service, and price.

The Basic Principles Of Premier Aluminum Llc

Buyers significantly pick spreading distributors who have machining abilities. This can stay clear of conflict if problems are uncovered during machining. If a third celebration is machining, it may cause "finger-pointing" concerning who is at mistake. Is it a casting problem or a machining problem? If the spreading vendor finds a problem throughout machining, the issue is solved faster with no conflict over whose fault it is.

Problem or no, integrated machining streamlines the supply chain and minimizes handling time and shipping price prior to the product makes it to the client. What do you need from your casting vendor? Are you trying to find someone to simply provide a steel element to your front door or do you need much more? If you do not have in-house metallurgy knowledge, confirm that the supplier can provide advice in choosing the correct alloy based on your specific application.

Others will certainly surpass the letter of the PO to assist you conserve time and money. Do you have requirements for both ferrous and non-ferrous alloys? Some shops are minimal or specialized. Make sure the distributor can fulfill all your material or alloy demands to get rid of the requirement for several vendors.

What Does Premier Aluminum Llc Mean?

Research the vendor's internet site. Talk to a sales representative or service associate.

Light weight aluminum is additionally lightweight and has great rust resistance, making it perfect for applications where weight and longevity are necessary variables. Furthermore, light weight aluminum spreading is a cost-effective method of manufacturing, as it requires less energy and resources than various other approaches. Iron spreading, on the various other hand, includes putting molten iron into a mold and mildew to produce a wanted form.

The 45-Second Trick For Premier Aluminum Llc

Iron spreading is also able to stand up to high temperatures, making it appropriate for use in applications such as engine components and commercial machinery. However, iron spreading can be more expensive than aluminum spreading as a result of the greater price of basic materials and the energy needed to melt the iron. When making a decision in between aluminum spreading and iron spreading, it is very important to take into consideration the details requirements of the application.

In verdict, both aluminum spreading and iron spreading have their very own distinct benefits and negative aspects. There are three sub-processes that fall under the classification of die spreading: gravity die spreading (or irreversible mold and mildew casting), low-pressure die casting and high-pressure die spreading. To get to the ended up product, there are 3 primary alloys made use of as die casting product to select from: zinc, light weight aluminum and magnesium.

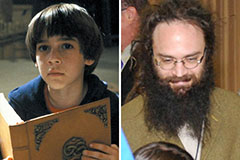

Barret Oliver Then & Now!

Barret Oliver Then & Now! Daniel Stern Then & Now!

Daniel Stern Then & Now! Jonathan Lipnicki Then & Now!

Jonathan Lipnicki Then & Now! Morgan Fairchild Then & Now!

Morgan Fairchild Then & Now! Nicki Minaj Then & Now!

Nicki Minaj Then & Now!